About Insulating roofs

Approximately a quarter of the heat lost from an average house goes through the roof, so minimising this should be one of your priorities. For our insulation fitters, insulating roofs is a straightforward job, as laying insulating material between the joists is a cheap, quick and quite effective.

There’s however a wide range of insulating materials we lay and it is our job to investigate which type will suite your circumstances best:

1). Blanket insulation, which is made from glass fibre wool or rock fibre is widely available in the form of rolls that fit snuggly between the joists.  All types are non-flammable and are proofed against damp and vermin. Similar material, cut to shorter lengths, is also sold as “baths”. Some blanket insulation is wrapped in plastic that serves as a vapour barrier and reduces direct contact with fibres that could irritate the skin. However, unbacked blanket is the cheapest and it is perfectly suitable for laying on the loft floor.

All types are non-flammable and are proofed against damp and vermin. Similar material, cut to shorter lengths, is also sold as “baths”. Some blanket insulation is wrapped in plastic that serves as a vapour barrier and reduces direct contact with fibres that could irritate the skin. However, unbacked blanket is the cheapest and it is perfectly suitable for laying on the loft floor.

2). Rigid sheet insulation,

a type of foamed polystyrene or polyurethane which our insulation fitters will install between the rafters of a sloping roof. This type of insulating material allows ventilation between the insulating material and the roof tiles or slates to avoid condensation after it is fitted.

a type of foamed polystyrene or polyurethane which our insulation fitters will install between the rafters of a sloping roof. This type of insulating material allows ventilation between the insulating material and the roof tiles or slates to avoid condensation after it is fitted.

3). Foiled quilt,

is usually used when the rafter are to narrow to accommodate slab or rigid sheet insulation and it is simply stapled to the underside of the roof timbers.

is usually used when the rafter are to narrow to accommodate slab or rigid sheet insulation and it is simply stapled to the underside of the roof timbers.

4). Rigid-foam decking,

usually used if you plan to use your loft as a storage space and our insulation fitters usually lay this foam panels with flooring-grade moisture-resistant chipboard bonded on top surface. We always recommend to have blanket insulation laid between the joists before planning to have fixed this foamed polystyrene panels on top of the joists.

usually used if you plan to use your loft as a storage space and our insulation fitters usually lay this foam panels with flooring-grade moisture-resistant chipboard bonded on top surface. We always recommend to have blanket insulation laid between the joists before planning to have fixed this foamed polystyrene panels on top of the joists.

About Insulating walls

We have a couple of methods for insulating the walls into a house which are likely to be determined by the type of construction:

1). Cavity or solid walls are usually found in houses build after 1920 and certainly after 1950 (2 skins of masonry with a gap between them to reduce the likelihood of water penetration). Although heat loss is slightly slower through a cavity wall than one of solid brick, that does not  substantially reduce the cost of home heating. However, having our insulation fitters filling the cavity with insulation prevents circulation, trapping air in millions of tiny pockets within the material. This can reduce heat loss through the wall by as much as 65%. Solid walls requires different treatment, in this case, our insulation fitters will install polystyrene boards over the external face of the walls and a consistent coat of water-proofed render will be applied over the polystyrene boards.

substantially reduce the cost of home heating. However, having our insulation fitters filling the cavity with insulation prevents circulation, trapping air in millions of tiny pockets within the material. This can reduce heat loss through the wall by as much as 65%. Solid walls requires different treatment, in this case, our insulation fitters will install polystyrene boards over the external face of the walls and a consistent coat of water-proofed render will be applied over the polystyrene boards.

2). Cavity insulation,

it is the most cost-effective for homes that have properly controlled central heating. Heating without controls simple increases the temperature, instead of saving on fuel bills. This type of insulation it is not practical for flats unless the whole building will be insulated at the same time.

3).Dry-lining,

is it another method suitable for solid and cavity wall, by lining the inner surfaces of the walls with insulation. This involves a great deal of effort, depending on the amount of alteration to joinery, electrical fittings and plumbing required, but it does provide and opportunity for selective insulation, concentrating on those rooms that are likely to benefit most.

is it another method suitable for solid and cavity wall, by lining the inner surfaces of the walls with insulation. This involves a great deal of effort, depending on the amount of alteration to joinery, electrical fittings and plumbing required, but it does provide and opportunity for selective insulation, concentrating on those rooms that are likely to benefit most.

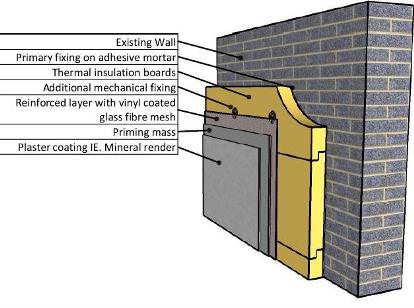

4). Exterior-wall insulation

or cladding the exterior of the house with polystyrene panels is is an expensive solution to insulate your house but it is efficient and will spoil the appearance of the building. The exterior wall-insulation it is installed by our professional insulation fitters and it can only be considered if the house is builded with solid masonry walls.

or cladding the exterior of the house with polystyrene panels is is an expensive solution to insulate your house but it is efficient and will spoil the appearance of the building. The exterior wall-insulation it is installed by our professional insulation fitters and it can only be considered if the house is builded with solid masonry walls.

The laminate

The laminate  This type of flooring provides the beauty and warmth of a real hardwood surface, but is cheaper than the solid wood boards. A softwood core is sandwiched between a thick veneer of decorative hardwood and a balancing veneer of softwood on the underside. The hardwood surface comes ready-finished with a durable coating of lacquer. Engineered boarding is manufactured as snap-together strips that make real-wood flooring as easy to be laid as laminate.

This type of flooring provides the beauty and warmth of a real hardwood surface, but is cheaper than the solid wood boards. A softwood core is sandwiched between a thick veneer of decorative hardwood and a balancing veneer of softwood on the underside. The hardwood surface comes ready-finished with a durable coating of lacquer. Engineered boarding is manufactured as snap-together strips that make real-wood flooring as easy to be laid as laminate.